In the evolving landscape of sustainability, a major difficulty for the global composites industry is the dilemma of recycling composite structures. Many companies are working to find solutions to this emerging challenge.

Enhancing the recycling processes of composites

During the last years, the Taiwanese company SWANCOR HOLDING LTD (further referred to as “Swancor”) contributed to the advancement of composite recycling with a technology for which the company was named the 2023 JEC Composites Innovation Awards Winner.

Swancor, represented in the Northern European region by distributor Bjørn Thorsen A/S, has developed a cutting-edge recyclable composite solution consisting of “EzCiclo” epoxy resin and “CleaVER” technology. These innovations enable recycling in composite applications like wind turbines, sporting goods, transportation, etc.

Kasper Jalander, Sales Director at Bjørn Thorsen A/S, which is also distributing Swancor’s standardized range of vinyl ester and epoxy resins, highlights the complexity of the composite industry’s recycling dilemma and the interest which EzCiclo and CleaVER have sparked at customers. “The challenge for the composite industry in general is the recyclability of the materials because a composite contains several materials, such as a carbon or glass fiber, together with matrix materials like vinyl ester, polyester, epoxy or other resins,” says Jalander. “We have sent samples to a number of companies and, even though the product is currently at an early stage, customers have shown big interest in the concept” continues Jalander.

EzCiclo recyclable thermosetting epoxy resin and CleaVER technology

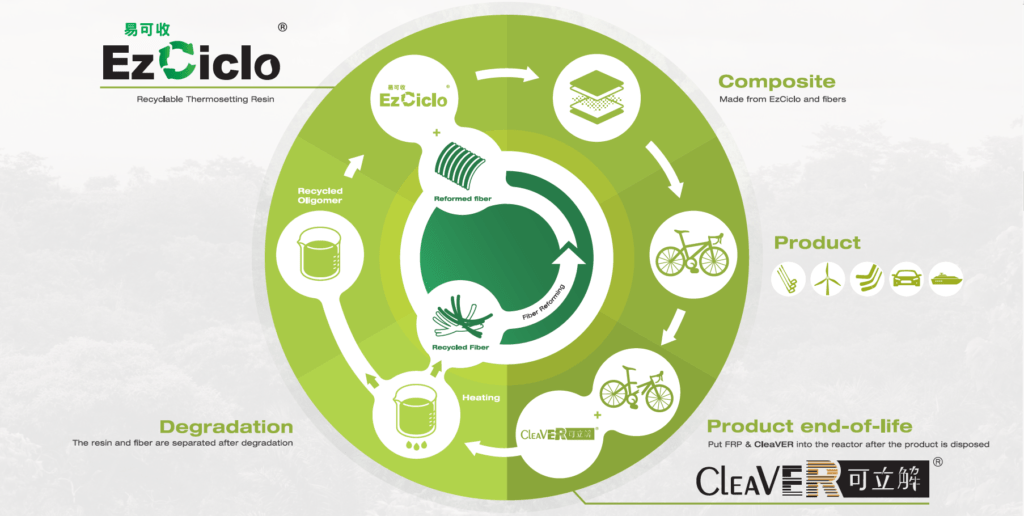

Swancor’s two new products, EzCiclo and CleaVER, offer solutions which enable recycling and reuse of composite parts. EzCiclo, a recyclable and reusable epoxy resin, was invented by Swancor in 2021 and solved the problem of non-recyclability of thermosetting epoxy resin since its invention in 1935. It has also dispelled the negative stigma surrounding fiber-reinforced plastic (FRP) or composite materials. When used in conjunction with glass or carbon fiber composites, it could be recycled and degraded via CleaVER technology.

Utilizing CleaVER technology, end-of-life composites undergo a transformative process. Fibers are separated from resins, paving the way for their reuse into new applications. The resin is recycled into an oligomer which is then used to produce the corresponding resin again. Before the actual degradation process, the FRP must be cut into smaller pieces, so it can fit into the reactor and speed up the degradation process. This Swancor innovation can be applied across a range of industries, like: wind energy, sporting, or transport industries and manufacturing processes like: infusion, pultrusion, prepreg, filament winding, hand-lay-up and others.

Advantages of Swancor’s recycling system

Compared with existing composites recycling methods: pyrolysis method and solvolysis method, Swancor’s recycling system demonstrates following benefits:

- No need to change the current wind blades production process and equipment

- No need to crush FRP before the decomposition process

- No waste solvent and waste gas in the recycling process

- Recycled fibers show equivalent mechanical performance to new fibers

- Oligomer could be reused

- Produces a minuscule carbon footprint

- Meet RoHS and REACH

Kasper Jalander also says that the recycling process does not require waste solvents or waste gas, which means that no pollution is generated. Instead, a degradable agent is used to break down products from a range of manufacturing processes. “Once separated and dried in an oven, the fibers can either be used in masterbatch for injection molding together with PP/ABS/PA, fiber mats or SMC/BMC” says Jalander.

The case of wind turbine blades

An area where Swancor’s recycling system can be very useful is the wind energy industry. For many years, one of the challenges to transition to wind energy has been the disposal of wind turbine blades. The standard method of disposal is burying and incineration due low cost, but this raises concerns from an environmental perspective. Recycling and reusing wind turbine blade materials is one of the solutions to this global problem and it can be achieved by using Swancor’s recyclable and reusable epoxy resin EzCiclo, due to which glass or carbon fiber composites could be recycled and degraded via their CleaVER technology.

Wind blade producers can significantly benefit from Swancor recyclable thermosetting resins. Some strategic partnerships have already been set in place, marking a pivotal milestone for Swancor in advancing towards green circular economy. With existing recycling capabilities in Taiwan and China today, Swancor and their partners can also contribute to establishing a robust recycling infrastructure across regions like Europe or US in the years to come.

Swancor’s contribution to zero-carbon era

Due to the visible signs of climate change, more than 140 countries have committed to the “Paris Agreement” to reach the goal of net-zero emissions by 2050. The European Union’s Carbon Border Adjustment Mechanism (CBAM) is set to go into force in 2026. Carbon reduction is no longer an environmental issue, but it has solid economic support as all industries are now moving towards net-zero emissions and sustainable operations.

Swancor is fully committed to tackling this issue by offering eco-friendly products and recycling composite solutions for customers to reach this goal. “Swancor will continue developing and improving their products and Bjørn Thorsen will remain an important European partner contributing with local distribution and industry expertise,” concludes Jalander.